Within a production line, the different workstations are increasingly being automated to enhance the profitability and productivity of a company. Therefore, employees must follow a specific sequence of steps, while observing their working hours, all in complete safety.

It is then paramount to ensure the proper operation of a manufacturing chain, the productivity of all employees as well as their safety. As a result, using clocks will enable employees to keep an eye on the time, PA systems and safety devices will be of paramount importance to communicate important information in a noisy environment, as well as in all frequented areas of the site. Eventually, a time server will ensure the reliable and accurate synchronisation of all these equipment, to avoid any disruption of activity.

| Industrial sector | Areas of application | Example of solutions |

|---|---|---|

| Manufacturing industry | Synchronisation of production lines, optimisation of processes in real time | Industrial clocks, NTP time servers, LED displays |

| Automotive industry | Management of assembly lines, monitoring of production planning | Timestamping systems, synchronised clocks, display of production rate |

| Agri-food industry | Monitoring critical times for processing and preserving products | Clocks for humid areas, time servers for automation |

| Chemical industry | Planning and follow-up on production steps requiring accurate synchronisation | Robust time servers, displays for ATEX zones |

| Pharmaceutical industry | Traceability of manufacturing processes, compliance with GMP standards | Synchronised clocks, time servers for laboratories |

| Textile industry | Management of production planning, real-time optimisation of processes | Synchronised display systems for workshop management |

| Energy industry | Synchronisation of processes in power plants and power grids | Highly accurate time servers, displays for checkpoints |

| Electronics industry | Planning of manufacturing stages and synchronisation of equipment | Synchronisation solutions via GPS, synchronised clocks |

| Mining and metal industry | Coordination of extraction and processing equipment | Robust displays for harsh industrial environments |

| Logistics and warehousing industry | Flow management in warehouses, monitoring of production and delivery deadlines | Synchronised clocks, LED panels for logistical follow-up |

Displaying an accurate and identical time within an industrial site

Digital or analogue clocks can display a clear and accurate time information in all frequented areas of a production site. Indeed, employees of an industrial company must be able to read the time instantly and at a glance, to keep pace with the industrial activity and observe their working hours (clocking in, breaks, clocking out).

As a result, digital clocks placed up high in a manufacturing line ensure observance of working hours and the proper timing of each workstation. Besides, these clocks have been especially designed to withstand the demanding conditions of a production chain, such as extremely low temperatures and impacts. It is then essential to use robust and hermetic clocks, for example in refrigerated environments in the agri-food industry. Since they are recess mounted, digital and analogue clocks meet hygiene standards required in the sector, withstand impacts and avoid dust building up.

Administrative areas such as offices, hallways, break rooms or the reception hall are equipped with clocks in order to guarantee time synchronisation in the whole industrial site. These areas are likely to be equipped with analogue or digital clocks, especially designed to fit in this type of indoor area, thus ensuring optimum reading.

Eventually, loading docks and workshops are large outdoor areas requiring accurate time display, visible from afar. Subject to wide temperature variations, impacts and dust, digital clocks fit perfectly in this type of environment, thus offering excellent readability.

Implementing time synchronisation in the industry sector

If time display within an industrial site is of paramount importance, it is equally important to ensure reliable and accurate synchronisation of all equipment. Indeed, it is essential that all clocks and equipment installed in an industrial company display an identical time, to ensure the smooth running of all operations, avoid manufacturing delays and guarantee continuous and efficient production flow.

Automation ensures the continuity of manufacturing activity regardless of fluctuations in human resources, and reduces the risk of accidents. In fact, the industrial sector integrates more and more solutions in order to optimise activity, such as robots, sensors and control systems, or artificial intelligence. However, it is important to analyse the different risks at stake when using these different solutions, such as breakdowns, manufacturing delays and cyberattacks, that might paralyse all activities.

As a result, it is paramount to secure complex network infrastructures and synchronise all equipment and clocks across the production site by using a a time server and several protocols (NTP, PTP) to guarantee identical time information for everyone, as well as a continuous and stable production flow. It is also important to ensure the security and confidentiality of data transmitted constantly by the different machines, systems and products.

Within a production site, each manufacturing stage is timed and measured accurately to optimise activity, ensure profitability, and gain efficiency. This is why the performance of a production line is measured according to a certain number of indicators, and monitored on a regular basis to assess the productivity of a company, to support continuous improvement. A time server will timestamp each synchronised step and redistribute these timestamps to the relevant machines. As a result, a time server will ensure the traceability of each information, and follow-up of events in a secure way.

Ensure efficient communication in a production line

In a production site, the workday is marked by different key moments: clocking in, the different timed steps to be observed, break times, and clocking out. It is then important to ensure that working hours are observed, all in a noisy environment. To do so, it is required and mandatory to install PA systems in public facilities. This type of system enables to broadcast audio messages, bells and information across the whole industrial site, thus guaranteeing that working time is respected and optimised on manufacturing lines and workshops.

Loudspeakers are also of paramount importance in an industrial site to keep operators informed on a wide range of subjects, from a simple work break to a more serious safety problem. These have been especially designed to deliver sound quality superior to the ambient noise typical of an industrial environment.

In order to optimise the manufacturing chain and the workday, an industrial site can schedule different announcements and bells to be broadcast during the day. As such, employees of a production site will know exactly how to react and actions to carry out according to the message or the melody broadcast.

Ensuring employee safety in industrial sites

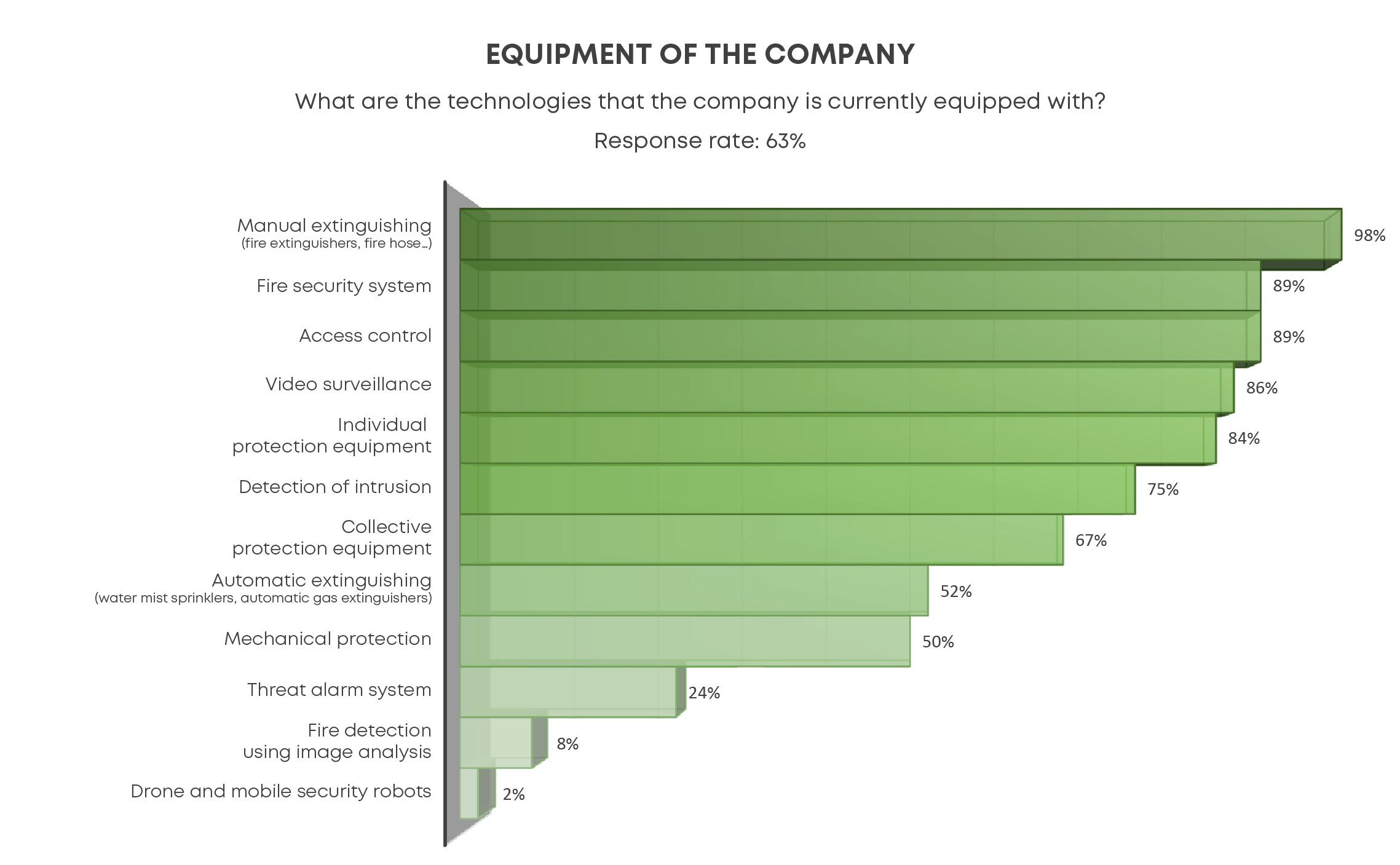

A recent study shows that only 24% of companies are equipped with a threat alarm system.

Yet, safety is of paramount importance within an industrial site, since it aims at protecting goods and people, while guaranteeing the sustainability of the company. Indeed, the ever-growing automation of industrial machines ensures greater productivity and safety, since manual work is often very dangerous. However, the zero-risk option does not exist, and it is paramount to implement risk prevention plans in the event of major incidents (technological, chemical, health, or intrusions). To do so, industrial sites and more generally public facilities, are required to establish a safety plan in order to analyse risks and take all necessary measures to keep employees safe, both indoors and outdoors.

Once the plan has been established, a production site is required to implement a prevention system in order to keep all employees informed at the same time and efficiently, in order to react as quickly as possible. Audio and alert broadcasting devices are essential tools for carrying out a safety plan from A to Z and ensuring uninterrupted production.

Expert in time synchronisation, distribution and PA systems, Bodet Time assists you with your industrial project. Discover our time servers, our range of clocks as well as our audio range to ensure the proper functioning and the security of your facility.